Security awareness training in manufacturing: The ultimate guide

Manufacturing has emerged as the most commonly targeted industry by cybercriminals, according to IBM. The stakes are particularly high — a successful breach can shut down production lines, compromise intellectual property and disrupt entire supply chains.

The human element makes manufacturing especially vulnerable. While some employees work primarily with industrial control systems or on production floors, others handle sensitive data and critical IT infrastructure. This diverse workforce faces unique challenges:

- Social engineers impersonating suppliers, safety inspectors and regulators

- Phishing emails containing fake invoices, compliance requirements or policy updates

- Physical security risks from unauthorized facility access

- Supply chain attacks targeting vendor relationships

- Industrial IoT device compromises

The financial impact of a data breach is severe. Manufacturing leads all industries in average breach costs at $4.88 million per incident, according to IBM's 2024 Cost of Data Breach Report. With anywhere from 68% to 90% of breaches involving human error, manufacturers must prioritize employee security awareness across all roles and responsibilities.

What’s in this guide?

This comprehensive guide will walk you through building and maintaining an effective security awareness program tailored for manufacturing environments. You'll learn how to:

- Address both IT and OT security awareness needs

- Deploy security awareness training that works for all employee types

- Protect critical systems and intellectual property

- Build a security-first culture on the production floor and in the office

Read on to learn more, or jump to a specific section:

- Understanding employee behavior

- Benefits of security awareness training

- Elements of a winning program

- Key technology and automation

- Implementing security awareness training

- Measuring security awareness training success

- Shaping the future

Understanding employee behavior

Manufacturing employees using industrial equipment face daily security challenges that can compromise data protection and operational safety without proper training.

Manufacturing employees make countless security decisions daily — from handling sensitive production data to interacting with industrial control systems. These decisions impact information security, physical safety and operational continuity. Without proper training, routine tasks can expose your organization to significant risks.

"One common misconception is that if you share information and resources with people, they will all process and apply it similarly," explains Keatron Evans, VP of Portfolio Product and AI Strategy at Infosec Institute. "However, everyone's logic varies, and people tend to make decisions subconsciously with the reactive side of the brain instead of the more logical side. This understanding is crucial for developing effective training approaches."

Manufacturing environments present unique behavioral challenges:

- Production floor workers may prioritize efficiency over security protocols

- Staff might grant facility access to people claiming to be inspectors or vendors without proper verification

- Employees working with industrial systems might not recognize cyber risks in operational technology

- Office staff handling supplier communications face sophisticated social engineering attempts

Creating lasting security awareness in manufacturing requires shifting mindsets from "security slows us down" to genuine engagement. Rather than viewing security as an obstacle to production goals, employees must understand how it protects operations and jobs.

Success comes from making security-relevant across all roles. When production workers understand how a compromised control system could cause safety incidents or when procurement staff recognize how vendor email fraud could disrupt supply chains, they're more likely to embrace secure practices. This connection transforms security from a corporate policy into a valued skill that benefits everyone.

Security awareness isn't about blame or fear. It's about empowering employees, from the shop floor to the executive suite, with knowledge and confidence to make secure decisions. When staff members understand what to do and why it matters, they're more likely to incorporate security best practices into their daily routines.

See Infosec IQ in action

![]()

Benefits of security awareness training

An effective security awareness program delivers measurable benefits across manufacturing operations. Beyond reducing security incidents, it helps organizations maintain production continuity, meet industrial compliance requirements, protect intellectual property and build trust with suppliers and customers.

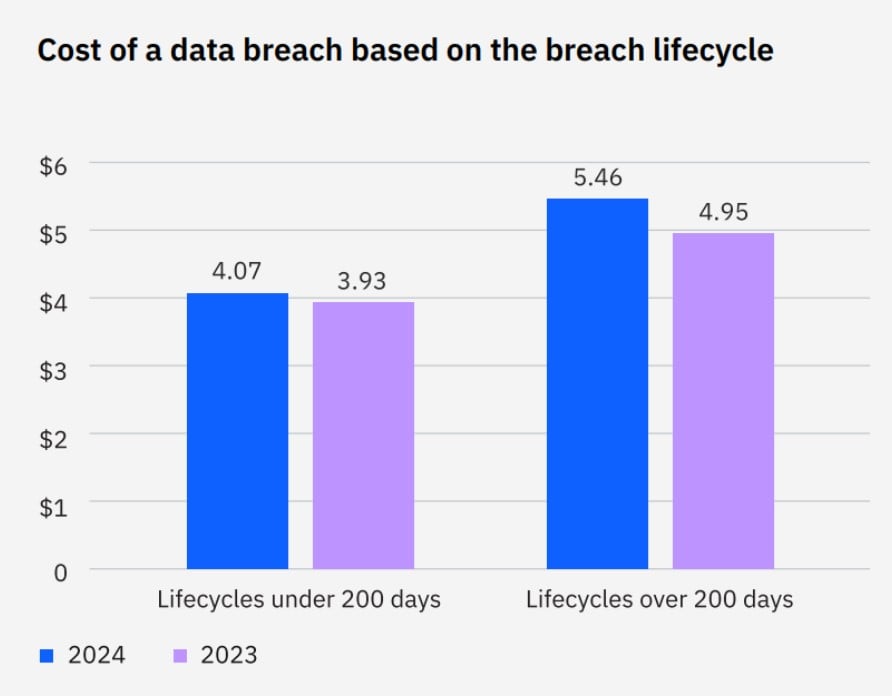

The financial case for training in manufacturing is compelling. Data from the IBM Cost of Data Breach Report 2024 shows that breaches with lifecycles exceeding 200 days cost organizations an average of $5.46 million — $1.39 million more than shorter lifecycles. In manufacturing environments, incidents involving human elements like:

- Compromised credentials (292 days)

- Phishing attacks (261 days)

- Social engineering (257 days)

Human-centered attacks take significantly longer to detect and fix, especially when they impact operational technology systems.

Security awareness training directly addresses some of these key risks facing manufacturers:

Production protection:

- Reduced risk of operational shutdowns from cyber incidents

- Fewer interruptions to just-in-time manufacturing processes

- Protected industrial control systems and IoT devices

- Maintained production quality and safety standards

Supply chain security:

- Better protection of supplier and customer data

- Reduced risk of vendor email compromise

- Stronger verification processes for third-party access

- Enhanced trust with business partners

Compliance and standards:

- Support for ISO 27001 certification requirements

- Alignment with NIST cybersecurity framework

- Maintenance of industry-specific standards

- Protection of intellectual property and trade secrets

The rewards extend beyond risk reduction. When employees understand security risks, incident response improves across IT and OT environments. This enhanced security posture helps manufacturers maintain business continuity, protect their reputation and build trust throughout their supply chain. Most importantly, it creates an environment where security becomes part of the DNA, with employees actively participating in risk reduction because they understand its importance to both production success and personal safety.

Elements of a winning security awareness program

A successful security awareness program in manufacturing drives measurable behavior change that reduces risk. Effective programs go beyond annual compliance training to create lasting security habits through continuous engagement and reinforcement —especially important in fast-paced production environments where traditional computer-based training may not always be practical.

Download our full Security awareness maturity infographic to learn more.

Manufacturing environments require training tailored to different operational contexts:

In production areas:

- Focus on physical security, access control and visitor verification

- Visual materials suitable for shop floor display

- Hands-on training with industrial control systems and IoT devices

- Clear procedures for reporting suspicious activities

In the office and engineering:

- Supply chain security and vendor verification

- Email security and phishing awareness

- Data protection for intellectual property and trade secrets

- Remote access and mobile device security

Program delivery must account for manufacturing's unique challenges:

- Multiple facility locations and shift schedules

- Areas with limited computer/network access

- Language and cultural differences

- Union requirements and agreements

Regular assessments help identify gaps and demonstrate program value. Organizations should monitor completion rates, incident reporting, physical security compliance and operational technology security metrics across all employee groups.

As programs mature, they should focus on what Right Hand Cybersecurity CEO Theo Nasser calls a "low barrier to training." This means delivering relevant content through familiar channels, making security concepts accessible on the production floor, and ensuring employees feel supported rather than policed in their security journey.

Get six free posters

Reinforce cybersecurity best practices with six eye-catching posters found in our free poster kit from our award-winning series, Work Bytes.

Key technology and automation to strengthen security awareness

Modern security awareness programs in manufacturing benefit from technologies that streamline delivery while enhancing effectiveness. From robots and autonomous vehicles to sensors and industrial control systems, manufacturing environments require specialized tools that protect both IT and operational technology.

Core training functions should automate key tasks across your organization:

- Phishing training simulation platforms safely test email security awareness while providing actual feedback.

- Learning analytics help identify which departments or roles need additional support and what types of training resonate most effectively.

- Dashboard reporting gives program managers visibility into progress and helps demonstrate effectiveness to leadership.

"The biggest problem is that factories are now connected to the internet,” explains Tom Molden, CIO of Global Executive Engagement at Tanium, on the Cyber Work Podcast. More and more factories are connected to the rest of the world, and this connectivity requires robust security awareness around industrial systems that may not have traditionally been considered security concerns.

The evolution of human risk management takes this integration further by connecting security operation center (SOC) tools directly with training platforms. This enables organizations to monitor IT and OT security events in real time, delivering targeted education based on actual behavioral data.

Rather than relying solely on scheduled training sessions, modern platforms can deliver brief reminders through digital displays, mobile devices or existing communication channels when they're most relevant. This "just-in-time" approach helps employees apply security concepts in their daily work while building lasting habits that protect both information and operational assets.

Implementing security awareness training that works for your organization

Begin your security awareness journey by thoroughly assessing your current position. Note that manufacturing environments face unique challenges around protecting IT infrastructure and operational technology — your assessment needs to consider both.

Essential first steps include:

- Review existing security incidents and employee feedback

- Map stakeholder groups and training needs

- Evaluate technical capabilities and resources

- Document compliance requirements

Manufacturing organizations must structure implementation around clear phases that respect production schedules and varying worker access to technology. This means designing modular training that can be delivered effectively across different facility types and shift patterns.

Training should address core manufacturing risks:

- Physical security and visitor verification

- Supply chain integrity

- Industrial control system protection

- Connected device security

- Data protection

Design your program with sustainability in mind. Consider how training will reach different employee groups — from office staff to production workers to external vendors. "Most people don't have that level of passion or care about security," notes Nasser. That’s why it’s essential to make training relevant to each role.

Manufacturing environments benefit from proven implementation strategies:

- Segment learners by role and facility type

- Align topics with actual security events and risks

- Maintain consistent reinforcement across shifts

- Include practical exercises for hands-on roles

- Partner with operational leaders to drive engagement

Consider leveraging established training providers rather than building everything internally. Pre-built, customizable programs can accelerate implementation while ensuring quality and compliance. Work with vendors who understand manufacturing's unique security challenges and can help your program evolve as technology advances.

Watch our webinar on Building an effective security awareness training program to learn more.

Measuring security awareness training success

Effective measurement in manufacturing environments requires tracking both traditional cybersecurity metrics and operational technology security indicators. Start by establishing baseline measurements that account for your facility types, worker roles and technology usage patterns.

"When calculating and measuring behavior, there is so much more to measure," explains Evans. Success in manufacturing security awareness means looking beyond basic completion rates.

Organizations should track how well employees apply security practices in their daily work:

- Training completion rates across all employee groups

- Phishing simulation performance (for applicable staff)

- Physical security compliance rates

- Visitor verification adherence

- Security incident reporting frequency and quality

- Compliance achievement status

- The manufacturing sector faces unique operational concerns that require specialized monitoring. Physical security, industrial systems and supply chain integrity all demand attention in your measurement strategy.

Regular evaluation helps identify which training methods resonate with different worker groups. Use this data to continually refine your program's content and delivery approach, ensuring it stays relevant as manufacturing technology evolves.

Get six free posters

Reinforce cybersecurity best practices with six eye-catching posters found in our free poster kit from our award-winning series, Work Bytes.

Shaping the future of security awareness training in manufacturing

Manufacturing security faces increasing challenges as operational technology becomes increasingly connected. Factories now manage complex networks of industrial IoT devices, automated systems and supply chain connections — each bringing new security considerations.

Your organization's security awareness program must evolve to address emerging challenges:

- Cloud migration of manufacturing systems

- Expanding industrial IoT deployments

- Complex global supply chains

- Advanced automation and robotics

Leadership plays a crucial role in building this security-minded culture. Beyond funding programs, leaders must demonstrate their commitment through action and support security initiatives across IT and OT environments.

Organizations should prioritize fresh, engaging content that reflects current manufacturing threats and technologies. Use integrated tools to monitor human risk factors across all facility types. Build collaboration between security, operations and production teams.

Success comes from keeping people at the center of your security strategy while adapting to manufacturing's evolving technology landscape. Start where you are, focus on steady progress and celebrate wins along the way.

To learn more:

- Watch our webinar to learn how to build an effective security awareness program

- Download our free 12-month manufacturing program plan to see the resources and training other manufacturers are using

- Speak to someone at Infosec to learn how we can help make your organization more cyber-secure.